Building the Factory of the Future with HOZA

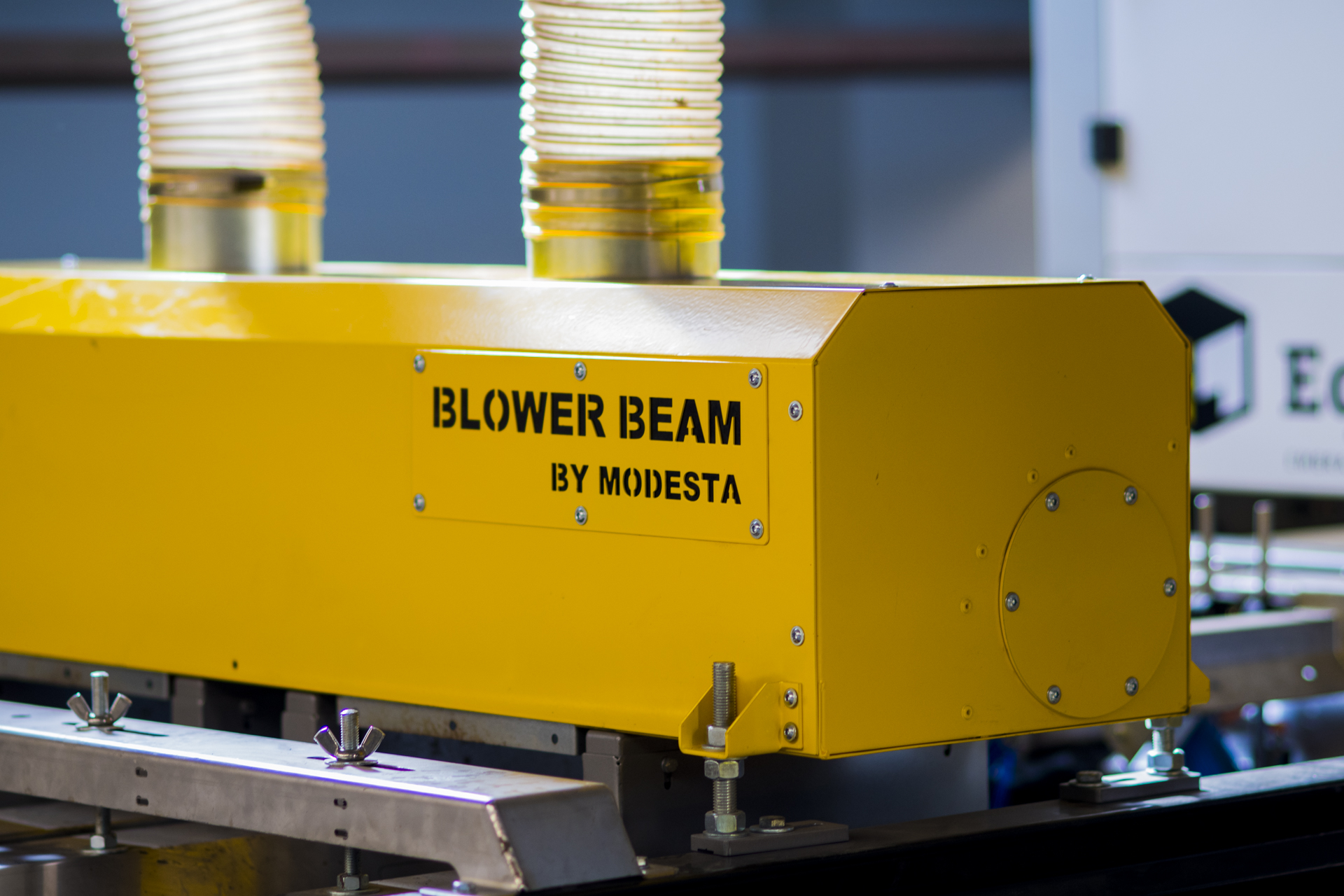

We meet grower Jim Hoogzand on a Saturday morning in his barn in Oudenhoorn. He welcomes us from his forklift as he transports onions for the initial tests and calibration of his recently installed Blower Beam by Modesta in line with the Eqraft Optical Grader .

As a fifth generation farmer from a pioneering family in the onion trade, Jim has inherited a strong entrepreneurial spirit. There are onions flowing through the veins of the Hoogzand family. Hoogzand has been a household name in the onion trade on the South Holland islands since 1870. Hoza, an abbreviation of the Hoogzand family name, was founded in Oudenhoorn in 1939. Jim’s father later started specialising in refining and propagating onion seed.

Based on years of experience and development, Jim now cultivates six different varieties of onions of the highest quality. The onion trade is changing fast and Hoza is changing with it. Whereas in the past Jim needed lots of manpower to keep the factory running, now he manages with just a handful of staff. Reasons for investing in the Optical Grader therefore include labour savings, cost control and products of the best possible quality.

The Optical Grader from Eqraft sorts onions internally and externally at high speed by size, weight and quality. During the process, the onions are first conveyed on a conveyor belt, after which they are separated and placed one by one on cups. The Blower Beam from Modesta removes loose skin and dirt from the onion. The onion is then conveyed through an infrared scan, also called the Sacmi Box, so that the internal quality can be checked. Bad quality onions are immediately conveyed away. Then the external quality of the onion is guaranteed by the double-sided inspection carried out by the Microtec ports. After the first inspection, the onions are turned around so that the other side can be inspected.